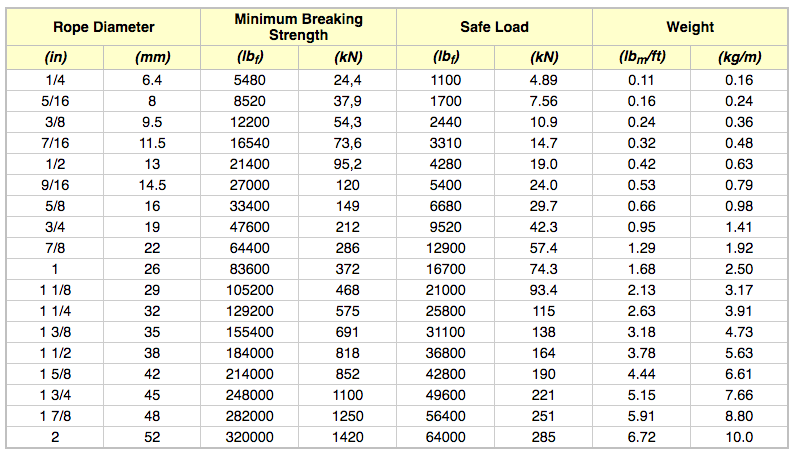

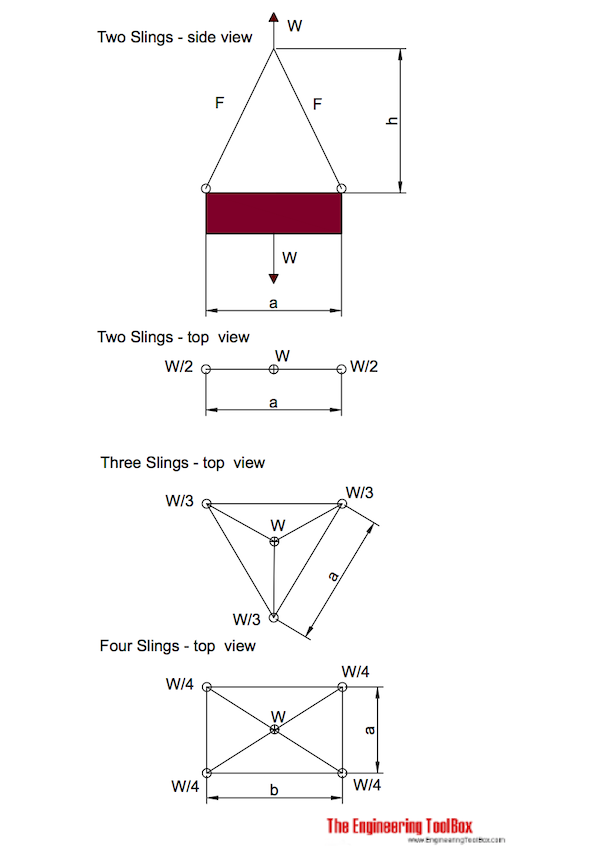

Wire rope safe working load the term safe working load swl of wire rope means the load that can be applied and still obtain the most efficient service and also prolong the life of the rope.

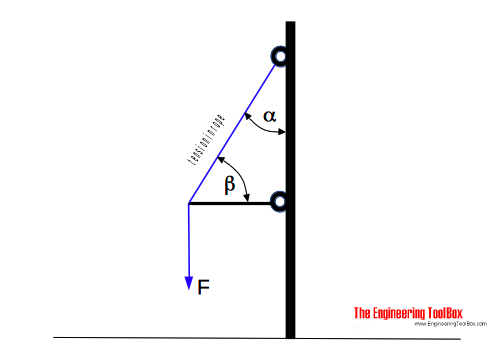

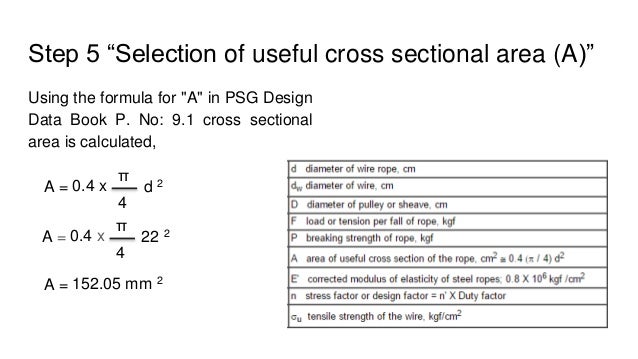

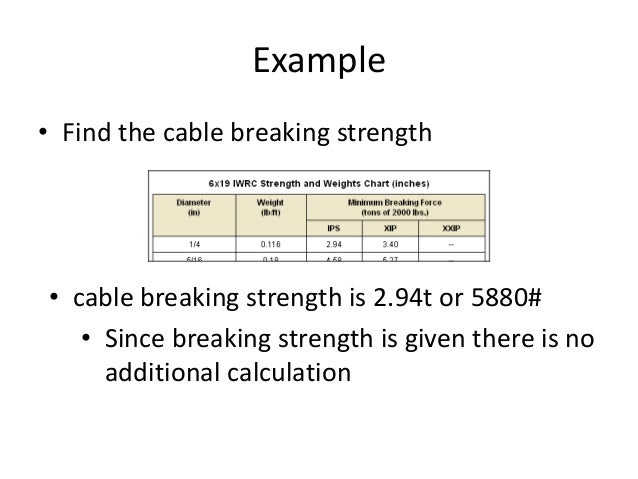

Strength of wire rope formula.

Rope diameter minimum breaking strength safe load weight in mm lb f kn lb f kn lb m ft kg m 1 4.

But it is essentially a collection of small filaments wound around each other in a manner that largely retains its shape when bent crushed and or tensioned.

This three layered design increases the density of our wire rope and reduces its risk of fraying or breaking allowing for superior tensile strength and durability compared to other wires cables and steel chains.

The formula for computing the swl of a wire rope is the diameter of the rope squared multiplied by 8 d x d x 8 swl in tons.

D is the diameter of the rope in millimeter the safe working load maybe taken as one sixth 1 6 of.

6 x 12 15d2 tons 500.

Wire multi strand wire flexible wire cable cord steelcord etc.

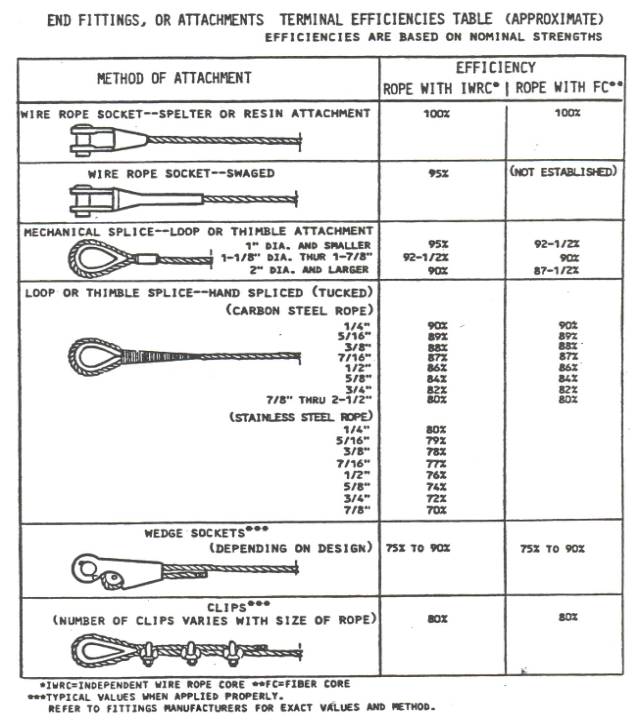

However a manufacturer may also test a rope s minimum tensile strength.

6 x37 21d2 tons 500.

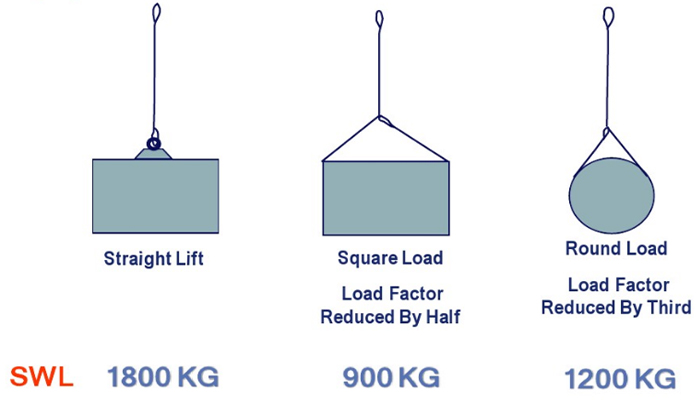

Wire rope and chain are the important part of the hoist which are closely bound up with the safe work load now let s talk about how to calculate the swl of ropes and chains.

All weight are calculated in kilograms kg.

A rope s minimum tensile strength is calculated in the same way but it takes the average strength rating and reduces it by 20.

Wire rope is also known by many other names such as.

This number is often used instead.

As we all known.

The wire rope is.

Charles missouri 63303 866 852 9714.

All diameters are measured in millimetres mm.

Diameter in mm squared the weight in kg.

The breaking stress of a flexible steel wire rope is given approximate by the following formula.

2086 exchange drive st.

A rope s working load is a different measurement altogether.